ABOUT US

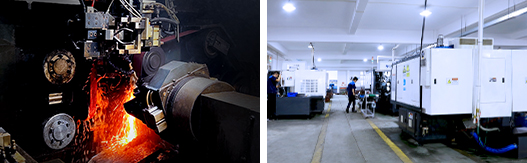

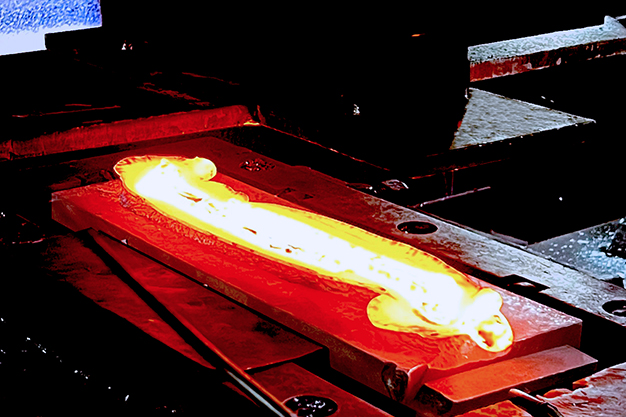

We designed different models of pliers for different requirements and loads, we use steel alloys that have been specially selected for the application and rolled according to our high specifications. Long lasting cutting capability when working with very hard wires, strength when working with high torque loads, and good resistance to corrosion are examples of these targets. The materials are then given their specific molecular structure in a number of coordinated heat treatment steps to produce the optimal relationship between hardness and toughness. These processes allow us to achieve the high degree of reliability, durability and service life that are the very definition of SANTU pliers.

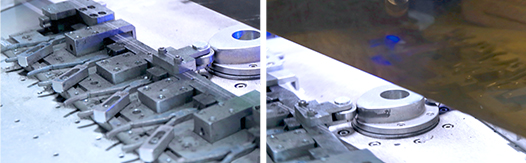

Compared with traditional induction high frequency, laser processing has a more stable positioning tool, so that the hardness of the cutting edge is more uniform,this process allows us to achieve the high degree of reliability, durability and service life that are the very definition of SANTU pliers.

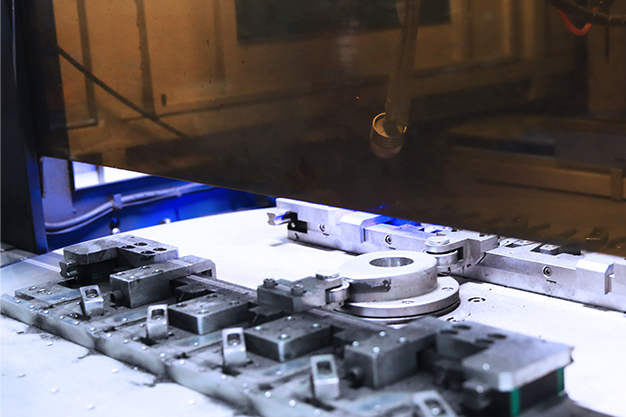

Compared with traditional manual polishing, the size accuracy of the automatically polished pliers is highly improved, and the size consistency is much better.